We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

Collaborations

Welcome to our project showcase demonstrating high-speed rotating machines designed to propel space missions and revolutionize transportation for a cleaner future. We continuously collaborate with partners to contribute our expertise in high-speed rotating systems.

If you are interested in collaborating on a project and would like to speak to us, please contact us.

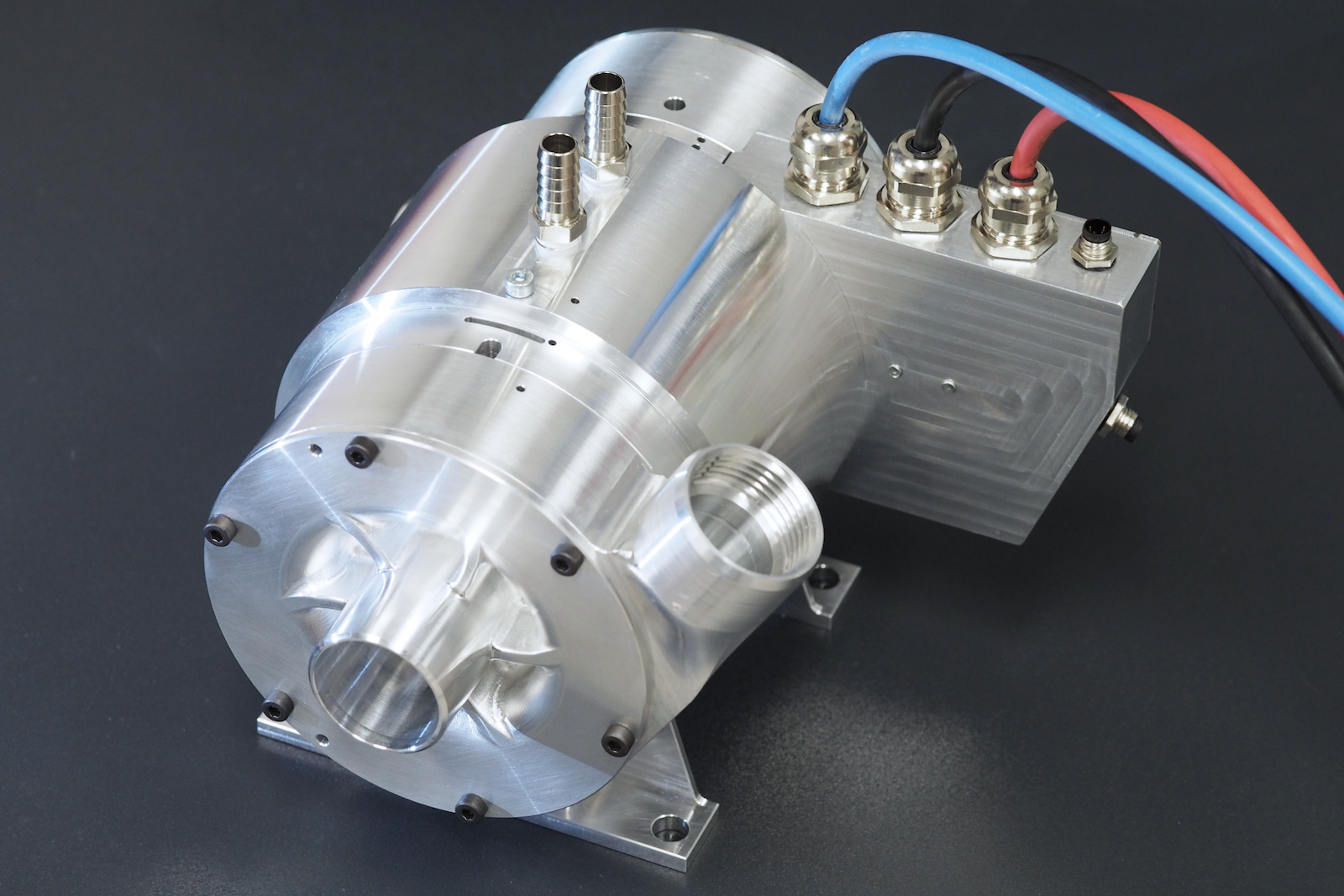

The project is focused on the development of a electrically driven pump for cooling circuits of large geostationary satellites using ammonia as a cooling medium. Inpraise Systems is a member of the contractor consortium together with Frentech Aerospace and LK Engineering and Thales Alenia Space. The consortium is led by Frentech Aerospace. Thales Alenia Space acts as a potential customer of the future application and sets the requirements for the equipment and provides technical support for development. Inpraise systems is responsible for system engineering and technical development of the motor drive.

* The project Coolant Pump De-Risking & Demostration is being implemented with financial support from the C3PFP Framework Project of the European Space Agency and the Ministry of Transport of the Czech Republic

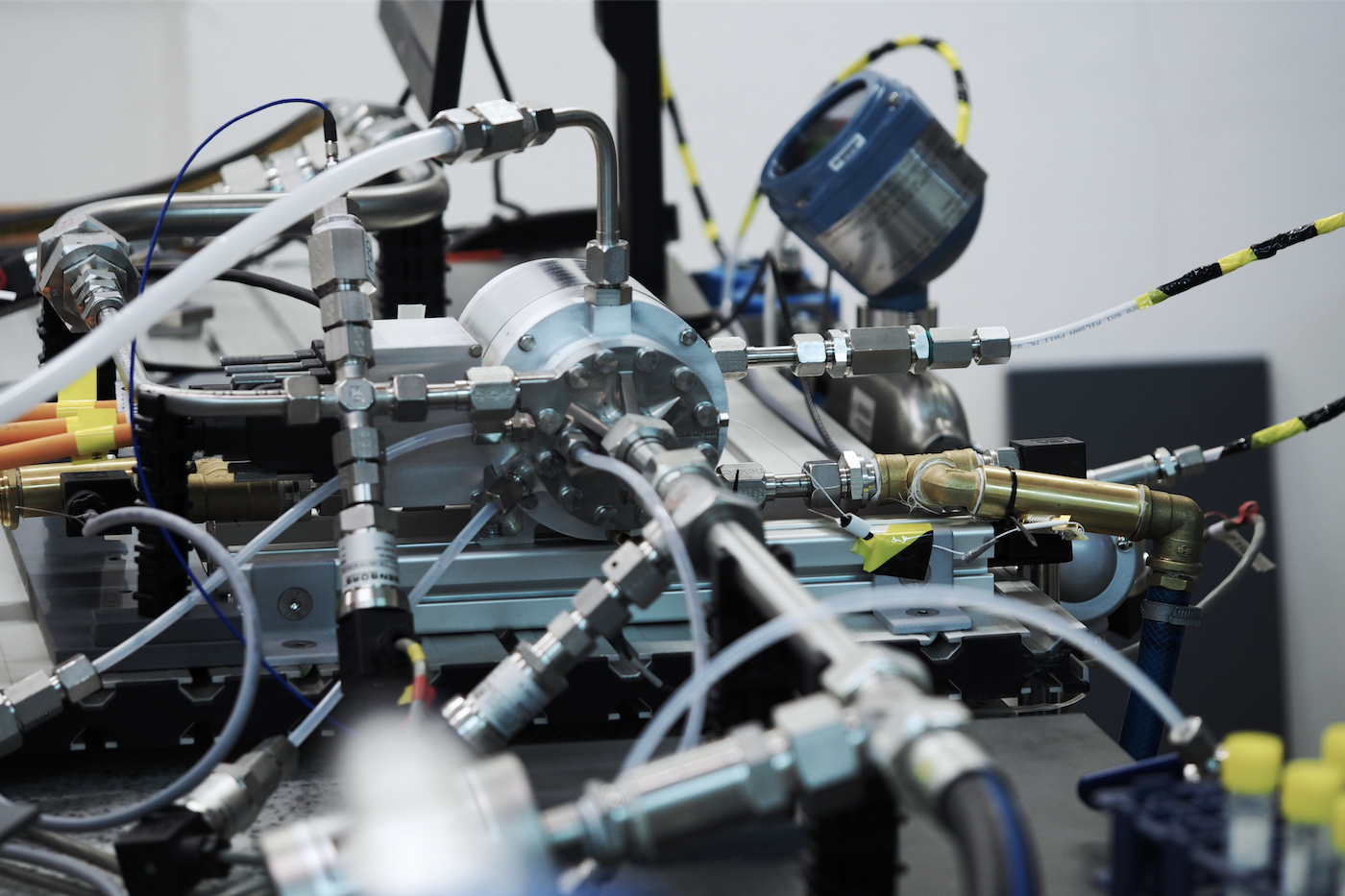

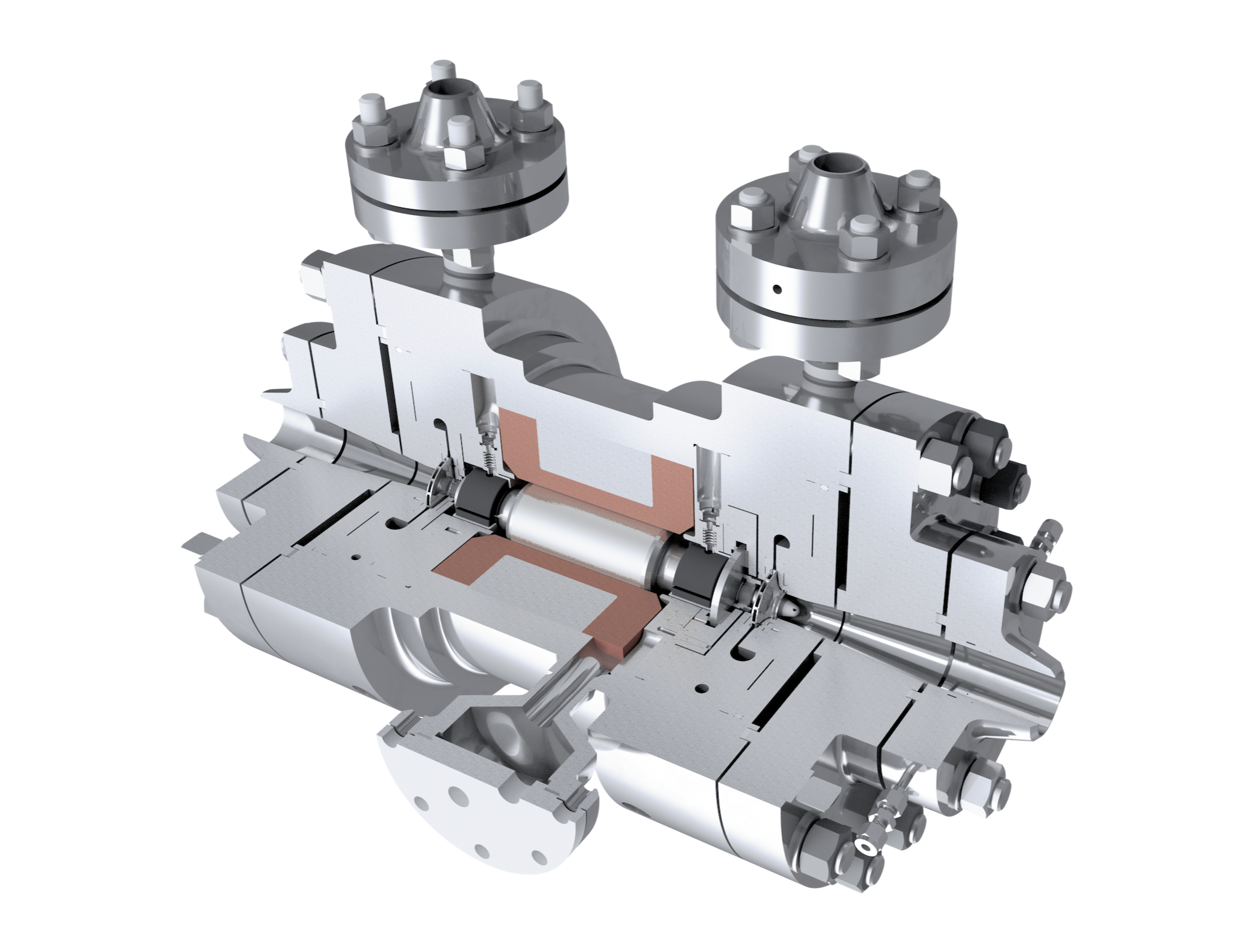

The project aims to develop an electrically driven pump suitable for a MON/MMH rocket engine with a nominal output of 2-7kN. The e-pump design conforms to the potential application for kick-stage engines of new-generation rocket carriers, landers, and other deep-space spacecraft. Inpraise systems acts as the main contractor for technical development.

* The 6 kN Storable Engine Electrical Pumps development project is being implemented with financial support from the C3PFP Framework Project of the European Space Agency and the Ministry of Transportation of the Czech Republic

The project aims to develop electrically driven pumps for the MON/MMH RELIANCE engine for the Argonaut lunar lander development under the European Large Logistics Lander [EL3] project. Nammo Raufoss AS is the prime contractor, with Inpraise Systems as the main contractor. Specialized departments at Brno University of Technology are also involved in significant collaboration under the project agreement.

* The Electric Pump (E-Pump) Systems PreDevelopment project is being implemented with financial support from the Human and Robotic Exploration [HRE] project and the Terrae Novae programme.

To minimize air pollution during rocket launches, extensive research has been dedicated to eco-friendly space propellants, contributing to the adoption of non-toxic alternatives. These propellants boast enhanced safety and ease of handling compared to traditional options, reducing associated costs in transport, storage, spacecraft development, and on-ground operations. In Europe, the allure of these non-toxic propellants is particularly evident in cost-effective micro-satellite missions and the evolving landscape of reusable vehicles. These efforts align with the completed initial development of the E-Pump system, designed for rocket engines utilizing environmentally friendly propellants. The pump's versatility also extends to accommodate other green propellants fuel, ensuring adaptability and sustainability in space exploration.

* The Green Storable Propellant Electric Pump Maturation project is being implemented with financial support from the Future Launchers Preparatory Programme [FLPP] of the European Space Agency.

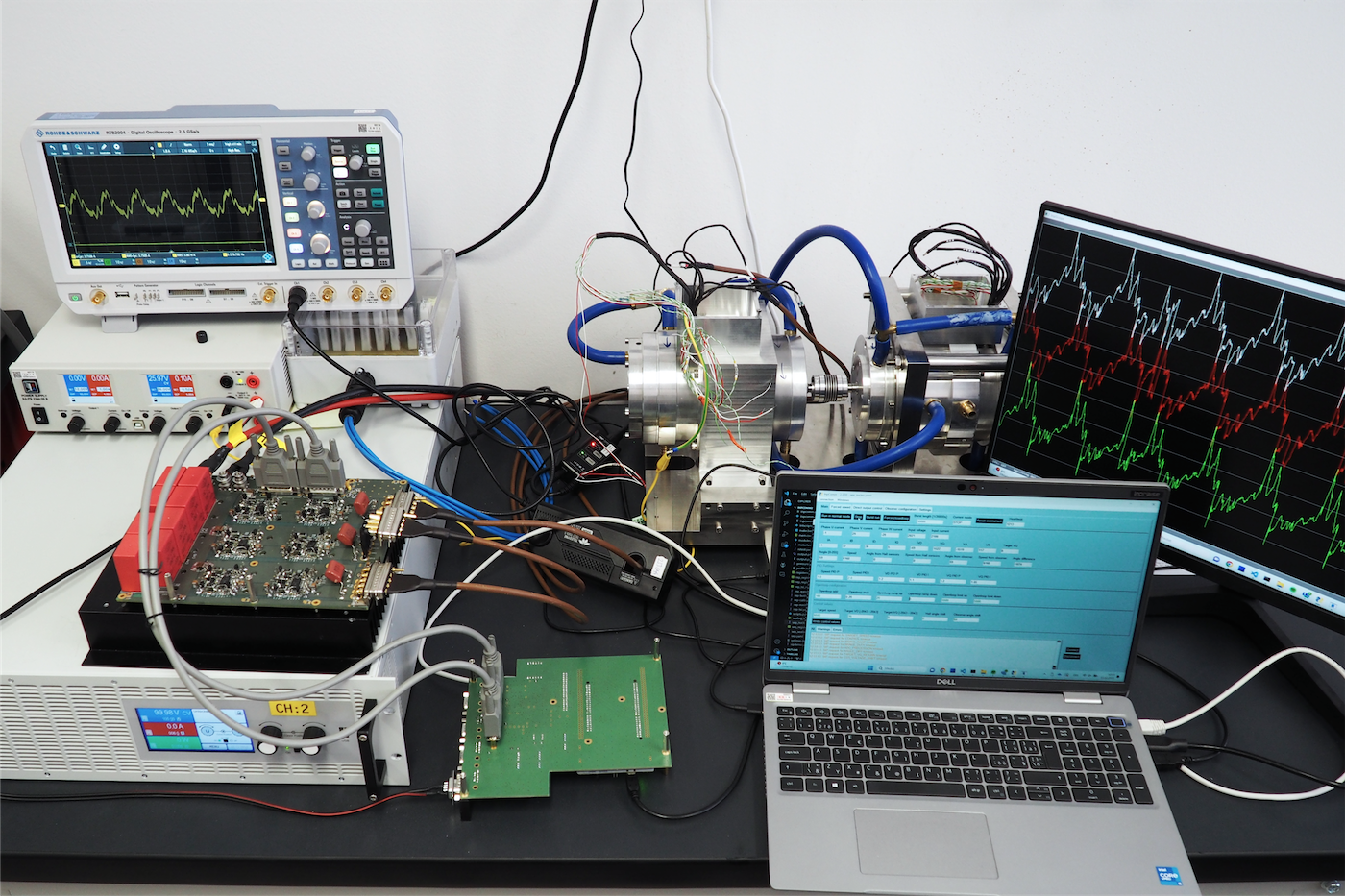

This project is dedicated to advancing research and development in the domain of high-speed electric compressors, specifically tailored for cutting-edge fuel cell power units and other compact, oil-free compressor applications.

A distinctive feature of this development effort lies in the utilization of air-lubricated tilting-pad gas bearings, imparting significant qualitative advantages to the compressor design. These bearings are inherently oil-free and exhibit minimal energy losses, making them an ideal choice for environmentally friendly applications. Key project objectives encompass the exploration of high-speed electromagnetic circuits, gas bearings, comprehensive technical parameter measurements, and rigorous testing to ensure the reliability and extended service life of high-speed rotating machines.

* Project FW03010647 – Development of an Electric Compressor for Clean Applications of New Generations of Hydrogen Fuel Cell Power Units is financed with state support from the Technology Agency of the Czech Republic and the Ministry of Industry and Trade of the Czech Republic under the TREND Program.

The primary objective is to develop an electrically powered micro turbocharger. This micro turbocharger is meticulously engineered for clean applications, specifically targeting the latest iterations of fuel cell power units. Distinguishing itself as a high-speed synchronous motor/generator adorned with permanent magnets, it boasts a dual-stage design comprising a compressor and a turbine. What sets this innovation apart is its pioneering gas-lubricated bearing technology, renowned for its exceptional resistance to wear, even under conditions of intermittent operation.

This groundbreaking gas bearing technology serves as a safeguard, ensuring that the air supplied remains uncontaminated by oil particles. By utilizing process gas (in this case, air) as the lubricating medium, our proposed solution offers a substantial advantage in terms of lower energy losses when compared to conventional oil-lubricated hydrodynamic or ball bearings. Through this project, we aim to revolutionize the landscape of micro turbochargers, delivering cleaner, more efficient solutions to power the fuel cell technologies of the future.

* Project CK02000051 – Development of a Micro Turbocharger for the Supply of Clean Air to Hydrogen Fuel Cell Systems is financed with state support from the Technology Agency of the Czech Republic and the Ministry of Transport of the Czech Republic under the DOPRAVA 2020+ Program.

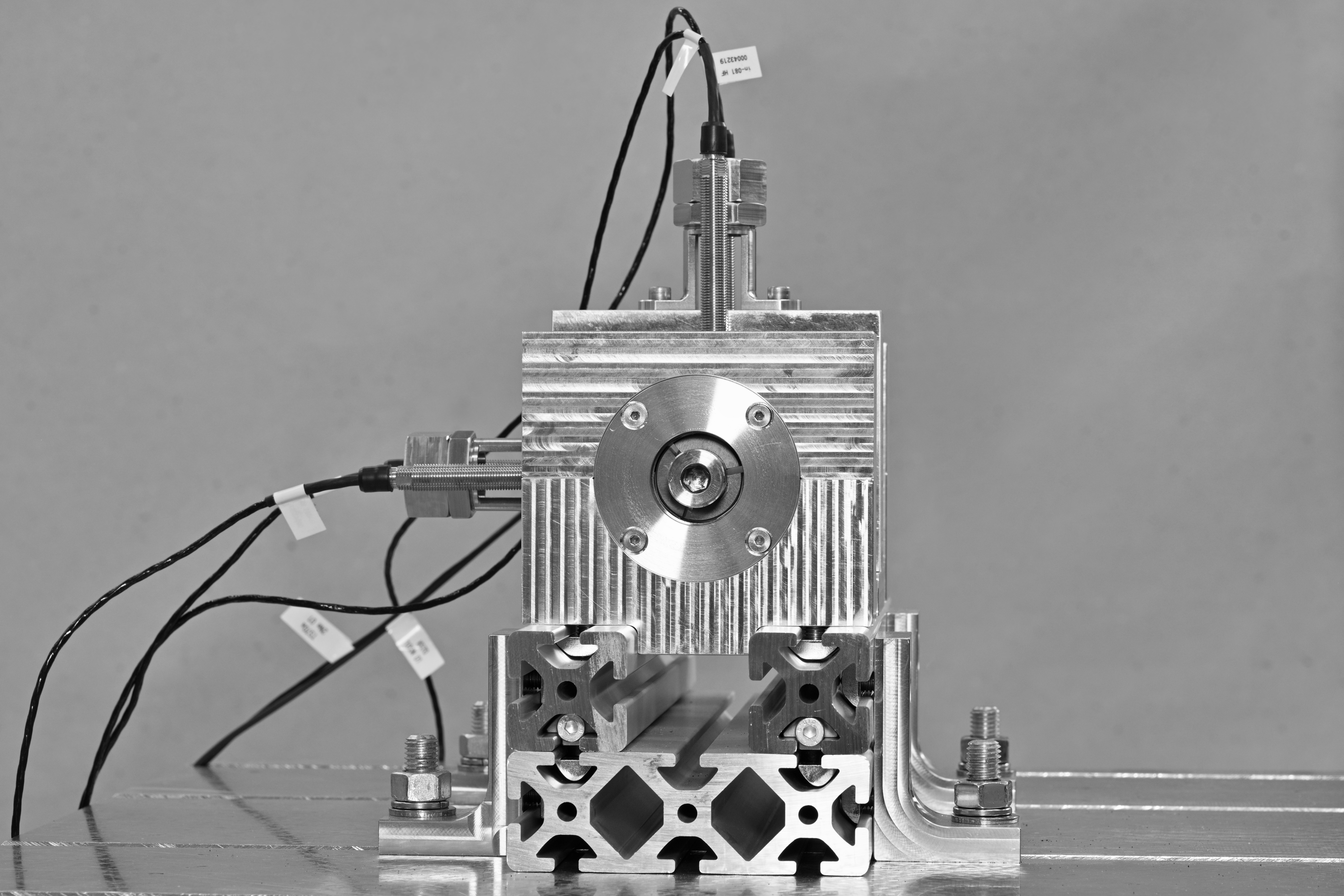

The objective of the project is the research and development of a serially produced gas-lubricated tilting-pad bearing prototype of a new generation for high-speed rotating machine applications, including production jigs and measuring methods for qualification, for clean air, flue gas, steam and other technical gases used in energy production. The project aims at developing a product for use in the domain of hydrogen applications, reducing the environmental impact by eliminating the use of oil lubricants, decreasing operating media leakage, and minimizing energy losses in rotating systems. The secondary objective focuses on determining allowable operating modes of gas-lubricated tilting-pad bearings to guarantee parameters for defined structural installations and operating modes.

* Project TK04030262 – Gas-Lubricated Aerodynamic Bearings for Hydrogen and Other High-Speed Applications is co-financed with the state support of the Technology Agency of the Czech Republic as part of the THÉTA Program.

The research project focuses on developing a flexible and efficient system for thermal energy storage, intended for the production of electrical or thermal energy. Scale-down prototypes of key components, including critical drive components and turbomachines for supercritical CO2 cycles, will undergo rigorous development, manufacturing, and testing to validate the feasibility of the final energy system. Operational experience gained through testing is crucial for economic evaluation and ensuring the competitiveness of the proposed solution. Leveraging compact thermal storage and conversion cycles, we aim to drive significant advancements in energy efficiency and sustainability.

* Project TK02030059 – Development of Innovative Systems for Efficient Energy Storage is co-financed with the state support of the Technology Agency of the Czech Republic as part of the THÉTA Program.

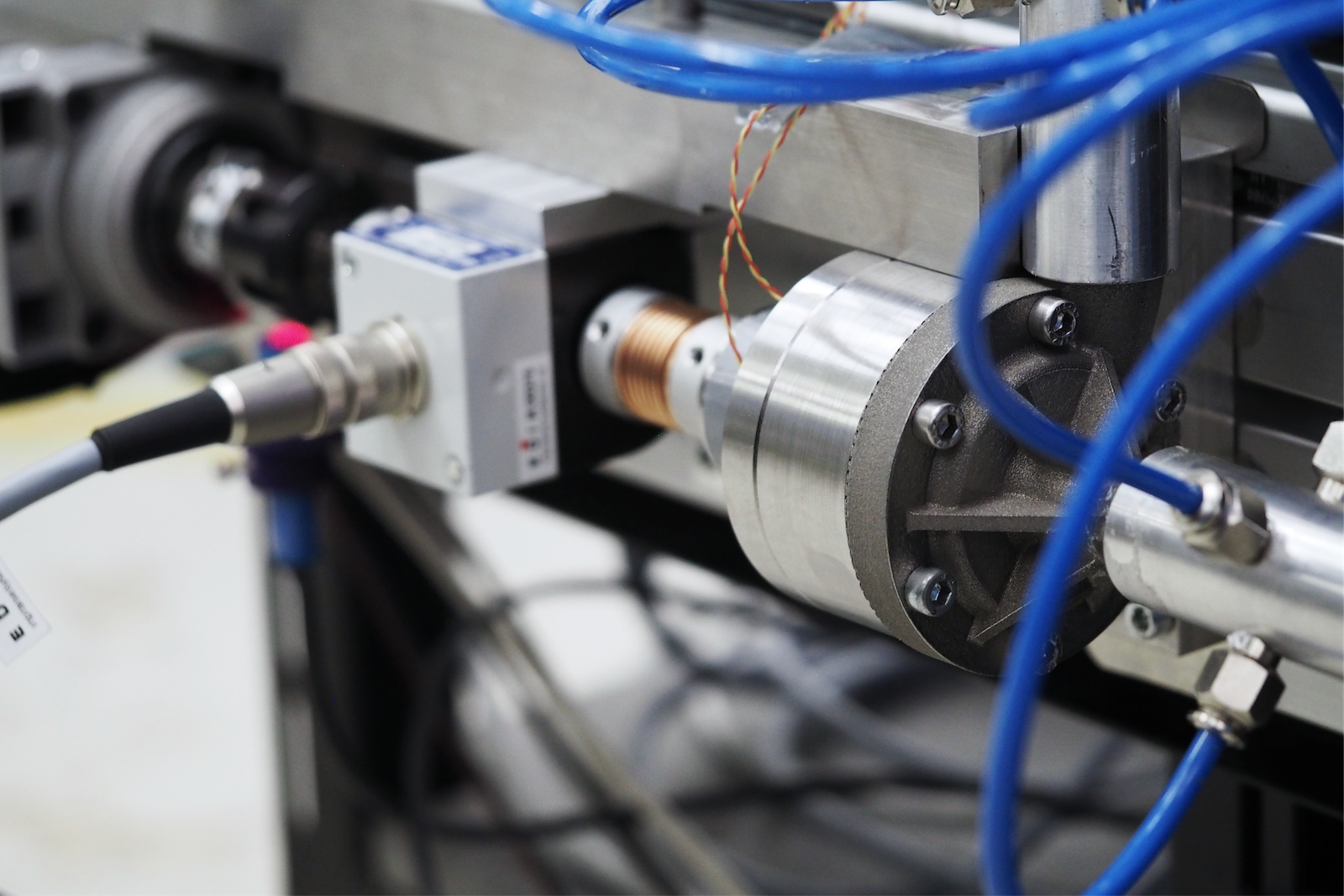

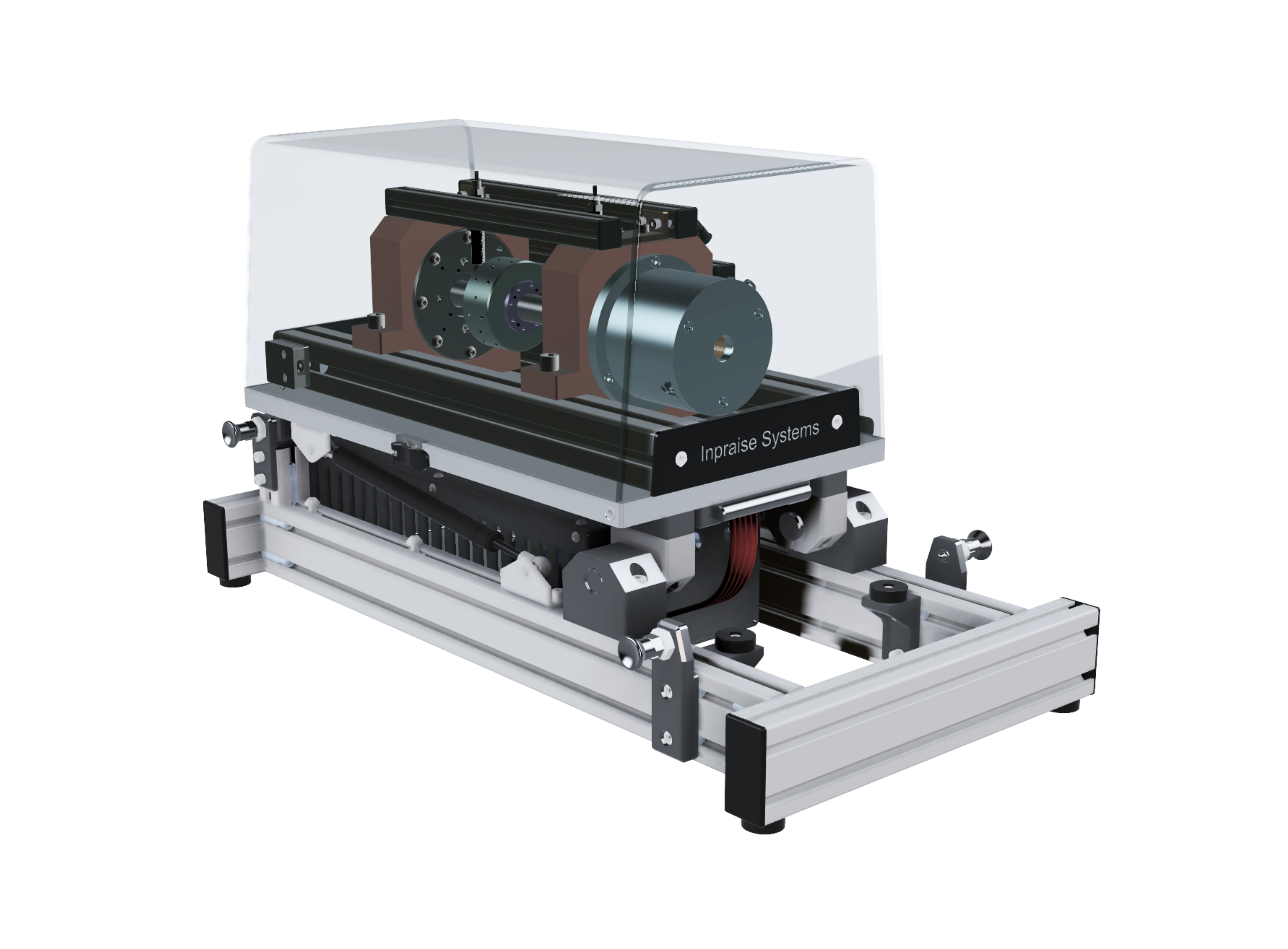

The project focuses on developing, assembling, and commissioning a specialized test bench designed to accurately identify, measure, and diagnose dynamic operational parameters of high-speed rotating machinery and rotor assemblies. Capable of handling exceptionally high operating speeds exceeding 20,000 rpm, the test bench aims to enhance reliability, efficiency, and operational lifespan. It will support the analysis of critical performance aspects, including rotor imbalance in both planar and multiplanar configurations, friction within bearing-mounted shafts, instabilities such as oil whirl and oil whip, as well as vibrations caused by rotor misalignment and component wear. This innovative test bench is intended to advance the development and optimization of high-speed rotating systems, ensuring improved performance and durability.

* Projekt CZ.01.01.01/05/23_009/0004544 – Vývoj a výroba prototypu zkušební stolice pro testování dynamických charakteristik vysokootáčkových točivých strojů je spolufinancován Evropskou unií.

Partnerships

Explore our network of industry leaders, research institutions, and innovators who join forces to drive the future of machinery. Together, we're shaping the landscape of high-speed rotating machines and revolutionizing the world of engineering.

DynLab is a joint R&D laborator established with the Institute of Solid Mechanics, Mechatronics, and Biomechanics of FME BUT to drive innovation and excellence in our shared field of research.

DynLab's core expertise lies in conducting cutting-edge research, precise measurements, and advanced simulations related to the dynamic behaviors of rotating machinery and specialized bearing systems.

The laboratory's interests are centered around computational analysis and dynamic measurements of rotor systems, calculations involving both damped and undamped rotor oscillations, and variable stiffness analyses within bearing supports.

Additionally, DynLab excels in computational modeling and performance measurements of specialized bearings utilized in applications featuring low-viscosity media and various gases.

Our company is a proud founding member of a consortium comprising various enterprises and institutions based in the Brno region. Drawing from our collective expertise, garnered through collaborations with esteemed organizations like ESA, ArianeGroup, OHB, Avio, Leonardo, and other leading players in the space industry, we've ventured into the commercial space market. Our mission is to extend our engineering services and offer collaborative opportunities for space projects to a broader spectrum of stakeholders.