We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

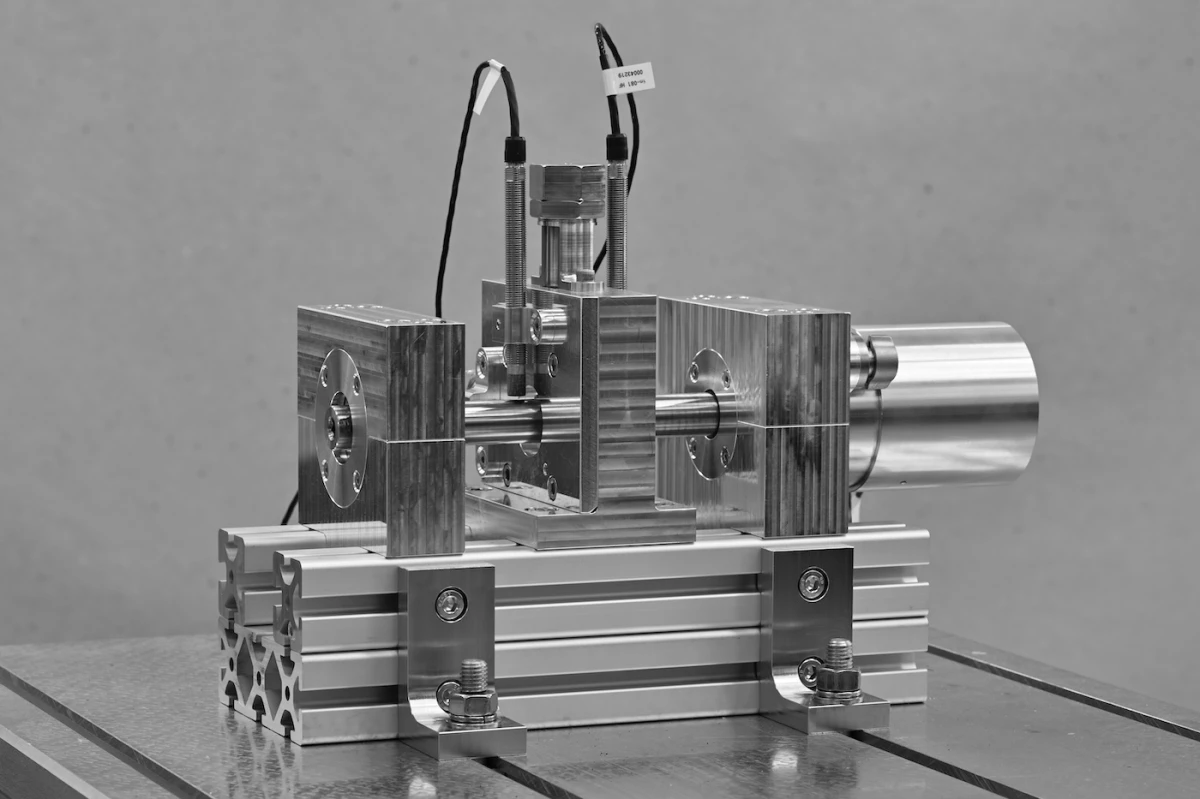

Rotating machines

In high-speed turbomachinery testing, specialized equipment with clutch-free, direct-drive technology is employed to test various components, including bearings, deflectors, composite banding, magnet fixtures, and rotational sealings (including dynamic seals), under extreme conditions. Precise measurements of high-speed bearing and sealing parameters, even at critical values within natural operational conditions, are obtained using appropriate instruments and sensors.

Rotor kits offer a practical hands-on platform for studying the principles of rotating machinery systems and subsystems. Equipped with various sensors, these kits support training and analysis of critical speed, frequency, time-based signals, orbital behavior, balancing, runout, rotor bow, resonance, and rotor dynamic studies. They are designed for easy assembly and experimentation. They are suitable for teaching - students seeking practical insights into rotational dynamics and balance and for researchers exploring innovative concepts in the field of rotating systems. The rotorkit's professional configuration is the best testing and measurement tool for industrial rotational machine development when using various gas and low-viscosity bearings.