We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

Rotating machines

Our development efforts are centered on pumps, compressors, turbines, motors, and generators engineered for high-reliability and mission-critical applications. In addition to design and development, we excel in prototyping, testing, and qualification, even up to flight-level standards. Our production scale targets small series production, typically up to approximately 100 units per year, with a specific focus on custom designs that prioritize critical parameters like lifetime, durability, and performance.

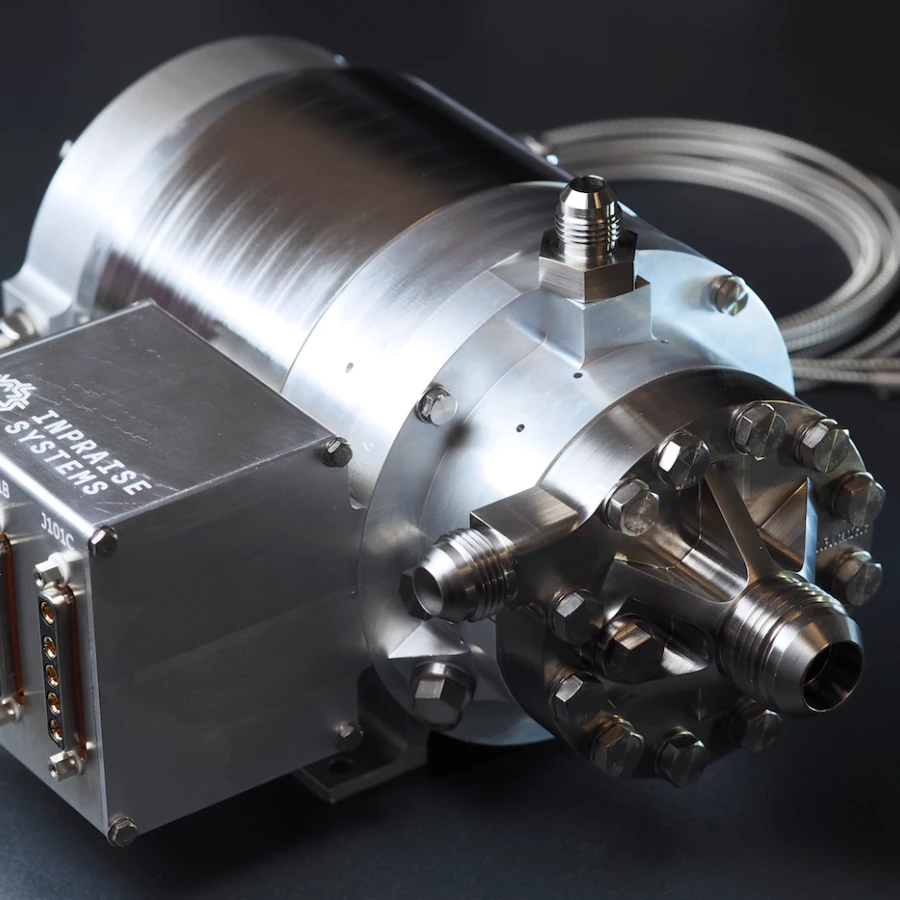

Electrically driven high-speed pumps for low-viscosity fluids use gas-lubricated drives to combine low-friction advantages with hermetic sealing and integrated centrifugal pumps, creating a maintenance-free system. These pumps excel in critical applications, including radioactive environments, toxic substance processing, ultra-clean conditions, and high-reliability, long-lasting usage scenarios.

Propellant feed system

Environmental control systems

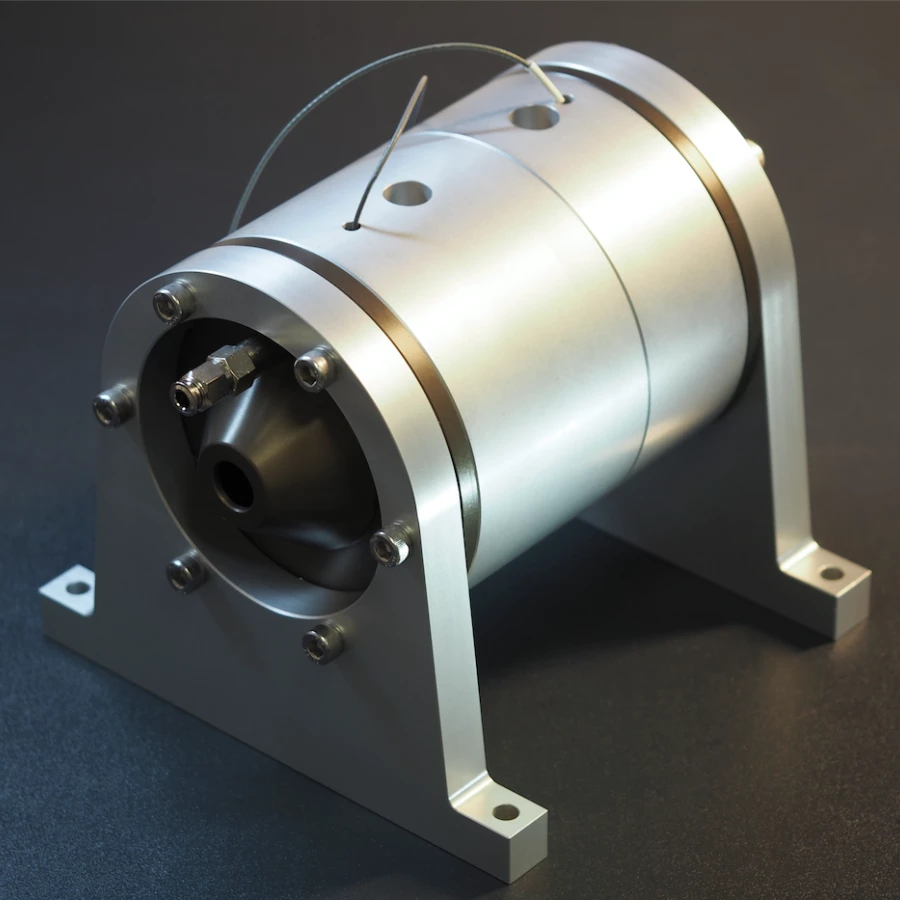

Electrically driven turbochargers and compressors offer versatile and hermetically sealed operation across a broad temperature spectrum, ranging from cryogenic to high-temperature applications. They demonstrate exceptional performance as standalone systems or when seamlessly integrated into vacuum or high-pressure machines, owing to their ultra-low friction and high reliability.

Air supply for fuel cell systems

sCO2 fluid management systems

High-speed electric turbines, coupled with high-frequency generators, produce electricity at extremely high speeds in hermetically sealed applications. Their direct-drive design simplifies systems, reducing complexity and friction losses. These turbines endure a wide temperature range, from cryogenic to supercritical high-temperature conditions, ensuring long lifetime and reliability.

Steam turbines and high frequency generators

Gas expanders

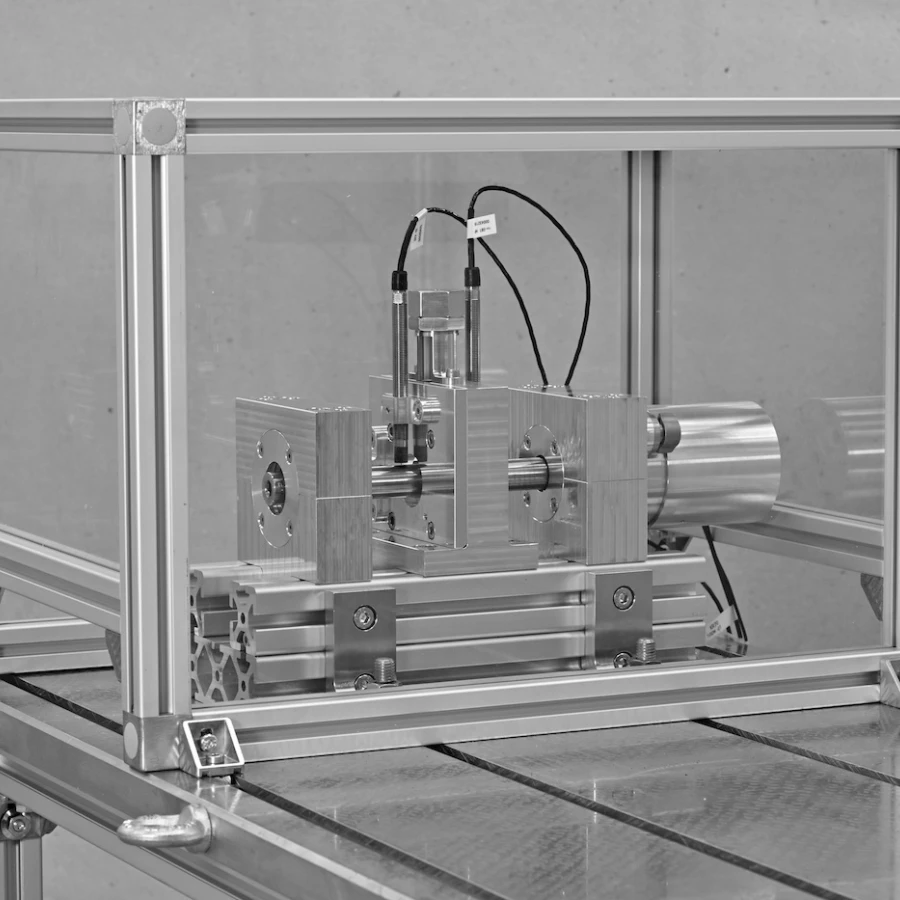

In high-speed turbomachinery testing, specialized equipment with clutch-free, direct-drive technology is employed to test various components, including bearings, deflectors, composite banding, magnet fixtures, and rotational sealings (including dynamic seals), under extreme conditions. Precise measurements of high-speed bearing and sealing parameters, even at critical values within natural operational conditions, are obtained using appropriate instruments and sensors.

Rotor kits for R&D and academia