We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

Bearings

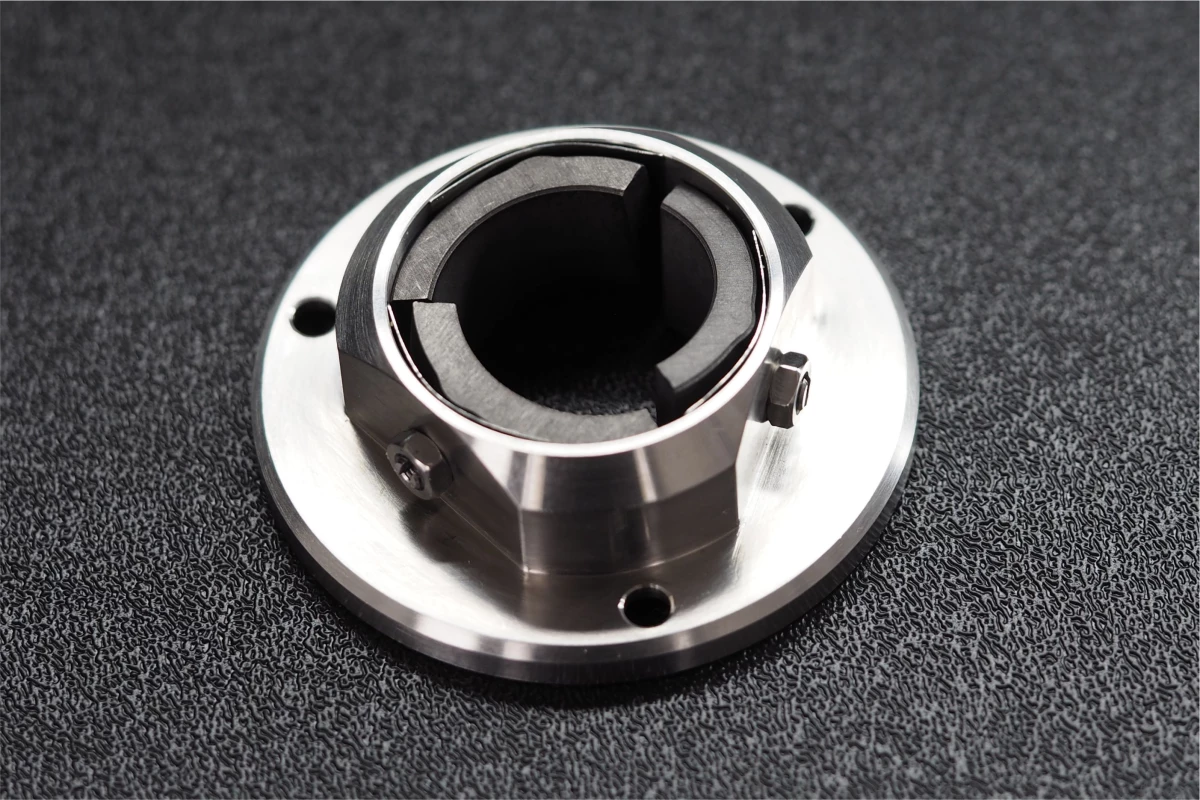

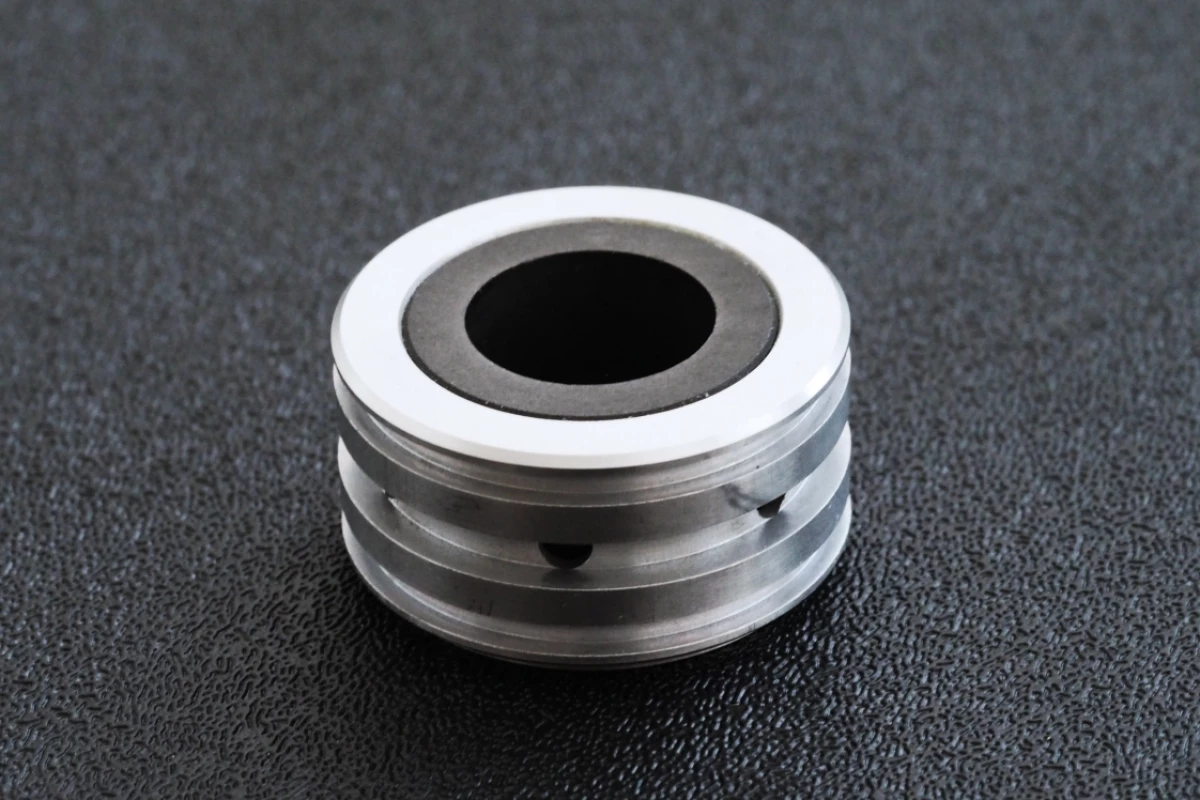

Design and manufacturing of maintenance-free radial and axial bearings with theoretically unlimited lifetime and exceptional operating precision and stability. Clean bearings applications eliminate the risk of contamination of the liquid or gaseous process media or the external environment with oil lubricants.

Low-viscosity hydrodynamic bearings, particularly tilting pad journal bearings, excel in durability, robustness, and performance. Their outstanding bearing stability, extended lifespan, and high start-stop cycle endurance make them ideal for high-performance and extreme applications. These bearings are used to be lubricated with process media, eliminating the necessity for additional lubrication and the associated risk of leakage and high system complexity.

Operational speed | Up to 80 000 rpm for canned systems with electrical drives |

Diameter | 6 – 60 mm |

Load radial/thrust | Up to 230 N |

Working temperature | Up to 660 °C |

The aerodynamic tilting pad journal bearings have the highest durability and longevity of all gas-lubricated bearings. Excellent bearing stability parameters, long life, and high start-stop cycle endurance predetermine them for high performance and extreme applications, working with various gases and no need for additional pressure. Their applications maintain the longest service intervals possible and due to their flexible configuration and used materials, can also be adapted to extreme high temperature and external vibration applications.

Operational speed | Up to 400 000 rpm [limited by subsonic bearing speed] |

Diameter | 6 – 60 mm, custom design considering factors like speed, axial force, working medium, and machine design |

Load radial/thrust | Up to 230 N |

Working temperature | Up to 230 °C |

The Aerostatic bearings have an excellent load capacity at low speeds and zero-wear start-ups. The operational conditions require continuous gas pressure feed while they offer minimal passive resistance and the capability to support loads even in the absence of relative motion between their sliding surfaces. They provide good stability and handle high loads. They can also operate complementary to aerodynamic bearings at start-up phases.

Operational speed | 0 – 200 000 rpm |

Diameter | 6 – 60 mm |

Load radial/thrust | Up to 2000 N |

Working temperature | Up to 230 °C |